Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Samsung MH FSBA Series

- Page 1 FJM IDU-PH_Cassette type_IM_31595A-04_EN.indd 26 2015-11-16 오후 4:52:24...

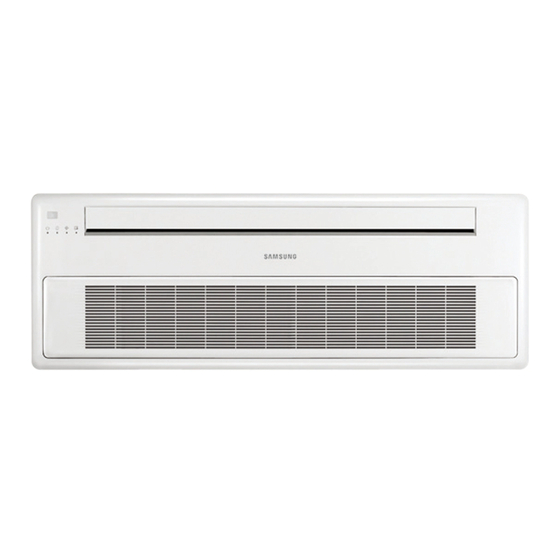

- Page 2 Cassette Type Series MH✴✴✴FSBA MH✴✴✴FMBA Air Conditioner installation manual imagine the possibilities Thank you for purchasing this Samsung product. DB98-31595A-04 EN ES PT FJM IDU-PH_Cassette type_IM_31595A-04_EN.indd 27 2015-11-16 오후 4:52:25...

-

Page 3: Table Of Contents

In order to prevent electric shocks, fires or injuries, always stop the unit, disable the protection switch and contact SAMSUNG ’s technical support if the unit produces smoke, if the power cable is hot or damaged or if the unit is very noisy. - Page 4 f The unit contains moving parts, which should always be kept out of the reach of children. f Do not attempt to repair, move, alter or reinstall the unit. If performed by unauthorized personnel, these operations may cause electric shocks or fires. f Do not place containers with liquids or other objects on the unit.

- Page 5 Safety precautions Power supply line, fuse or circuit breaker f Always make sure that the power supply is compliant with current safety standards. Always install the air conditioner in compliance with current local safety standards. f Always verify that a suitable grounding connection is available. f Verify that the voltage and frequency of the power supply comply with the specifications and that the installed power is sufficient to ensure the operation of any other domestic appliance connected to the same electric lines.

-

Page 6: Preparation For Installation

Preparation for installation When deciding on the location of the air conditioner with the owner, the following restrictions must be taken into account. General Do NOT install the air conditioner in a location where it will come into contact with the following elements : f Combustible gases f Saline air f Machine oil... -

Page 7: Deciding On Where To Install The Indoor Unit

Preparation for installation Accessories in the indoor unit case MH✴✴✴FMBA Pattern sheet Insulation cover band Insulation pipe Insulation drain hose Cable-tie Flexible hose M4x12 tapped screw Pad stopper Installation manual Safety net M4x12 tapped screw Deciding on where to install the indoor unit Indoor unit f There must be no obstacles near the air inlet and outlet. - Page 8 Space requirements for indoor unit MH✴✴✴FSBA MH✴✴✴FMBA The units must be installed according to distances declared, in order to permit accessibility from each side, either to guarantee correct operation of maintenance or repairing products. The unit’s parts must be reachable and removable CAUTION completely under safety condition (for people or things).

- Page 9 Deciding on where to install the indoor unit Drawing of the indoor unit MH✴✴✴FSBA Unit : mm(inch) 970(38.19) (5.31) 1036(40.79) 1074(42.28) Drain hose 1180(46.46) Name Description ➀ Liquid pipe connection ø6.35(1/4”) ➁ Gas pipe connection ø9.52(3/8”) ➂ Drain pipe connection OD 29(1.14"), ID 25(0.98") ➃...

- Page 10 MH✴✴✴FMBA Unit : mm(inch) 577~610(22.71~24.01) (Ceiling opening) 670(26.38) 476(18.74) (Suspension position) Suspension 48(1.89) 575(22.64) 48(1.89) bolt 4-M8~M10 Fresh air intake hole 210(8.27) 164(6.46) 244(9.61) 260(10.24) Description Name ✴✴030/035✴✴ ✴✴052✴✴ ➀ Liquid pipe connection ø6.35(1/4”) ø6.35(1/4”) ➁ Gas pipe connection ø9.52(3/8”) ø12.70(1/2”) Drain pipe connection OD 29(1.14"), ID 25(0.98")

-

Page 11: Indoor Unit Installation

Indoor unit installation It is recommended to install the refnet joint before installing the indoor unit. 1. Place the pattern sheet on the ceiling at the spot where you want to install the indoor unit. Since the diagram is made of paper, it may shrink or stretch slightly due to temperature or humidity. -

Page 12: Purging The Unit

Purging the unit From factory the unit is supplied and set with a pre-charge of nitrogen gas (inert gas). Therefore, all inert gas must be purged before connecting the assembly piping. Make sure all the nitrogen gas is purged out before installing the unit. If not, do not install the unit because leftover nitrogen could cause internal leakage. -

Page 13: Connecting The Refrigerant Pipe

Connecting the refrigerant pipe When installing, make sure there is no leakage. When recovering the refrigerant, ground the compressor first before removing the connection pipe. If the refrigerant pipe is not properly connected and the compressor works with the WARNING service valve open, the pipe inhales the air and it makes the pressure inside of the refrigerant cycle abnormally high. -

Page 14: Cutting/Flaring The Pipes

Cutting/flaring the pipes 1. Make sure that you have the required tools available (pipe cutter, reamer, flaring tool and pipe holder). 2. If you wish to shorten the pipes, cut it with a pipe cutter, taking care to ensure that the cut edge remains at a 90° angle with the side of the pipe. -

Page 15: Performing Leak Test & Insulation

Performing leak test & insulation Leak test To identify potential gas leaks on the indoor unit, inspect the connection area of each refrigerant pipe using a leak detector for R-410A. Before recreating the vacuum and recirculating the refrigerant gas, it is advisable to pressurize the whole system with nitrogen (using a cylinder with pressure reducer) at a pressure above 40 bar in order to immediately detect leaks on the refrigerant fittings. - Page 16 5. Select the insulation of the refrigerant pipe. - Insulate the gas side and liquid side pipe referring to the thickness according to the pipe size. - Indoor temperature of 30°C(86°F) and humidity of 85% is the standard condition. If installing in a high humidity condition, use one grade thicker insulator by referring to the table below.

-

Page 17: Drainpipe And Drain Hose Installation

Drainpipe and drain hose installation Care must be taken when installing the drainpipe and drain hose for the indoor unit so that condensate water is drained correctly outside. 1. Fix the flexible hose to the drainpipe. Drainpipe Flexible hose f The connection port of the flexible hose and PVC drainpipe must be fixed with PVC adhesives. - Page 18 Lift-up drain piping If it is necessary to increase the height of the drain hose somewhat, install a lift-up drain piping. 1. Connect a lift-up drain pipe top to the drain hose with an adhesive for PVC. 2. Wrap the insulation drain with a vinyl tape. 3.

-

Page 19: Connecting The Connection Cord

Connecting the connection cord • Always remember to connect the refrigerant pipes before performing the electric connections. When disconnecting the system, always disconnect the electric cables before disconnecting the refrigerant pipes. CAUTION • Always remember to connect the air conditioner to the grounding system before performing the electric connections. -

Page 20: Wiring Wired Remote Control (Optional)

Wiring wired remote control (optional) Connect the power cable, which is connected with the outdoor unit and supplied by another source, making sure that the power cable terminal should not be changed. The F3 and F4 communication cable may be cross-connected, however, it is recommended that they are connected to the corresponding F3 and F4 terminal. - Page 21 Assigning address to indoor unit 1. Before installing the indoor unit, assign an address to the indoor unit according to the air conditioning system plan. 2. The address of the indoor unit is assigned by adjusting MAIN(SW02). MH✴✴✴FSBA SW05 SW06 SW07 SW02 MAIN SW04 RMC...

-

Page 22: Additional Functions

Additional functions Function K1 K2 K3 K4 External room sensor Not use Centralized control Not use SW05 SW05 ❋ ❋ K1 OFF Heating mode : Setting temperature compensation value = 0°C(0°F) Thermo OFF Fan OFF MH✴✴✴FSBA Function K5 K6 K7 K8 Indoor temperature compensation for 2°C(3.6°F) 5°C(9°F) - Page 23 Installing the safety net & air blocking kits (Only for MH✴✴✴FMBA) Safety net Install the safety net after installing the connection cord and fixing electric component box cover. For your safety, you must install the safety net. For details about installing the panel, refer to the manual for the panel. 1.

-

Page 24: Troubleshooting

Troubleshooting Detection of errors f If an error occurs during the operation, an LED flickers and the operation is stopped except the LED. f If you re-operate the air conditioner, it operates normally at first, then detect an error again. LED Display on the indoor unit LED Display Indicators... - Page 25 Troubleshooting LED Display Indicators Green Yellow Green Orange Abnormal conditions Operating MH✴✴✴FSBA MH✴✴✴FMBA 1. 2 detection of refrigerant completely leak Displayed on appropriate indoor unit which is 2. 2 detection of high temperature COND operating Displayed on 3. 2 detection of high temperature DISCHARGE outdoor unit 4.

- Page 26 Memo FJM IDU-PH_Cassette type_IM_31595A-04_EN.indd 25 2015-11-16 오후 4:52:24...