Toro 22317 Operator's Manual

Compact utility loader

Hide thumbs

Also See for 22317:

- Service manual (602 pages) ,

- Operator's manual (40 pages) ,

- Operator's manual (40 pages)

Summary of Contents for Toro 22317

- Page 1 Form No. 3357-129 Rev A Dingo® 220 Compact Utility Loader Model No. 22317—Serial No. 270000001 and Up Register your product at www.Toro.com Original Instructions (EN)

-

Page 2: Introduction

Warning Service Dealer or Toro Customer Service and have the model and serial numbers of your product CALIFORNIA ready. Figure 1 identifies the location of the model Proposition 65 Warning and serial numbers on the product. Write the numbers in the space provided. -

Page 3: Table Of Contents

Contents Hydraulic System Maintenance ....33 Replacing the Hydraulic Filter .... 33 Changing the Hydraulic Fluid..... 33 Introduction ............2 Checking the Hydraulic Lines..... 34 Safety ..............4 Storage .............. 35 Safe Operating Practices ...... 4 Troubleshooting..........36 Slope Chart ......... 8 Schematics ............ -

Page 4: Safety

Safety hearing protection. Long hair, loose clothing or jewelry may get tangled in moving parts. Improper use or maintenance by the operator • Inspect the area where the equipment is to be or owner can result in injury. To reduce used and remove all objects such as rocks, toys, and wire which can be thrown by the machine. - Page 5 Tall grass can hide obstacles. barriers may result in injury as the traction unit • Use only Toro-approved attachments. backs up during operation if the operator is not Attachments can change the stability and attentive to the surroundings.

- Page 6 Make any necessary repairs before • Carefully release pressure from components restarting. with stored energy. • Use only genuine Toro replacement parts to • Disconnect the battery or remove the ensure that original standards are maintained. spark plug wires before making any repairs.

- Page 7 penetrate skin and cause injury requiring surgery within a few hours by a qualified surgeon or gangrene may result.

-

Page 8: Slope Chart

Slope Chart... -

Page 9: Safety And Instructional Decals

Safety and Instructional Decals Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or lost. 98-9051 108-9732 98-4682 108-9716 100-6141 1. Fast 4. Slow 2. - Page 10 Battery Symbols 98-8219 Some or all of these symbols are on your battery 1. Fast 3. Slow 1. Explosion hazard 6. Keep bystanders a safe 2. Throttle distance from the battery. 2. No re, open ame, or 7. Wear eye protection; smoking.

-

Page 11: Setup

Setup Step Step Checking Fluid Levels and Drive Chain Tension Installing the Valve Lever No Parts Required Parts needed for this step: Procedure Speed selector valve lever Before starting the engine for the first time, check the engine oil and hydraulic fluid levels and the Procedure traction drive chain tension. - Page 12 Battery terminals or metal tools could short against metal components, causing sparks. Sparks can cause the battery gasses to explode, resulting in personal injury. • When removing or installing the battery, do not allow the battery terminals to touch any metal parts of the traction unit. •...

-

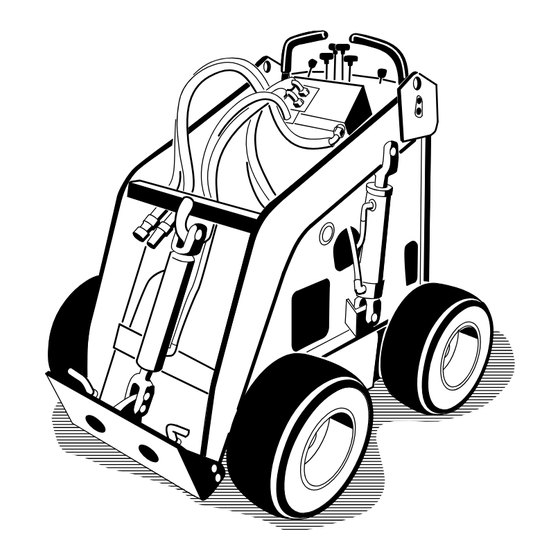

Page 13: Product Overview

Product Overview G005159 Figure 5 1. Mount plate 5. Fuel tank 9. Auxiliary hydraulic couplers 13. Air cleaner 2. Tilt cylinder 6. Wheel 10. Control panel 14. Counterweight 3. Loader arms 7. Operator platform 11. Lift points 4. Lift cylinder 8. - Page 14 To go straight, move both traction control levers equally. If you move the speed selector lever while To turn, move the lever located on the side you the traction unit is in motion, the traction want to turn back toward the neutral position unit will either stop suddenly or accelerate while keeping the other lever engaged.

-

Page 15: Specifications

66 inches (168 cm) Attachments/Accessories A selection of Toro approved attachments and accessories are available for use with the machine to enhance and expand its capabilities. Contact your Authorized Service Dealer or Distributor or go to www.Toro.com for a list of all approved attachments and accessories. -

Page 16: Stability Data

Stability Data The following tables list the maximum slope recommended for the traction unit in the positions listed in the tables. Slopes over the listed degree may cause the traction unit to become unstable. The data in the tables assume that the loader arms are fully lowered; raised arms may affect the stability. In each attachment manual is a set of three stability ratings, one for each hill position. -

Page 17: Operation

Operation Note: Determine the left and right sides of the machine from the normal operating position. Important: Before operating, check the fuel and oil level, remove debris from the traction unit, and check the tire pressure. Also, ensure that the area is clear of people and debris. You should also know and have marked the locations of all utility lines. -

Page 18: Checking The Engine Oil Level

Use unleaded gasoline (87 pump octane minimum). 2. Remove the key and allow the engine to cool. Leaded, regular gasoline may be used if unleaded 3. Clean around the oil dipstick (Figure 7). is not available. Important: Do not use methanol, gasoline containing methanol, or gasohol containing more than 10% ethanol because the fuel system could be damaged. -

Page 19: Checking The Tire Pressure

Checking the Tire Pressure Important: It is preferable to blow dirt out, rather than washing it out. If Maintain the air pressure in the tires as specified. water is used, keep it away from electrical Check the tires when they are cold to get the most items and hydraulic valves. -

Page 20: Driving The Traction Unit

move the choke forward again until the engine • To turn, move the lever located on the side you warms up. want to turn toward the neutral position while keeping the other lever engaged. 7. Move the throttle lever to desired setting. •... -

Page 21: Using The Cylinder Locks

Installing an Attachment 4. Position a loader arm cylinder lock over each lift cylinder rod (Figure 11). Important: Use only Toro-approved 5. Secure each loader arm cylinder lock with a attachments. Attachments can change the clevis pin and cotter pin (Figure 11). - Page 22 Figure 13 1. Mount plate 2. Receiver plate 5. Raise the loader arms while tilting back the mount plate at the same time. Important: The attachment should be raised enough to clear the ground, and the mount plate should be tilted all the way back.

-

Page 23: Securing The Traction Unit For Transport

6. Push the attachment male connector into the 5. If the attachment uses hydraulics, slide the female connector on the traction unit. collar back on the hydraulic couplers and disconnect them. Note: When you connect the attachment Important: Connect the attachment male connector first, you will relieve any pressure built up in the attachment. -

Page 24: Maintenance

Maintenance Note: Determine the left and right sides of the machine from the normal operating position. Recommended Maintenance Schedule(s) Maintenance Service Maintenance Procedure Interval • Replace the hydraulic lter. After the rst 8 operating • Torque the wheel lug nuts to 50 ft-lb (68 N⋅m). hours After the rst 50 •... -

Page 25: Lubrication

Lubrication Note: At the center of each front wheel hub is a grease fitting covered by a rubber cap. Fill these fittings with grease until the blue ring Greasing the Traction Unit around the fitting moves all of the way out toward you, then replace the cap. -

Page 26: Servicing The Engine Oil

5. Lightly tap the paper filter on a flat surface to remove dust and dirt (Figure 19). Figure 19 1. Paper element 2. Rubber seal 6. Inspect the paper filter for dirt, tears, an oily film, and damage to the rubber seal. Figure 17 Important: Never clean the paper element. - Page 27 Viscosity: See table below USE THESE SAE VISCOSITY OILS 10W-30 5W-20, 5W-30 Figure 21 1. Oil drain valve G000650 5. Open the drain valve by turning it Figure 20 counterclockwise, pulling out as you turn it (Figure 21). 6. When the oil has drained completely, close the Changing the Oil and Filter drain valve and remove the hose.

-

Page 28: Servicing The Spark Plugs

then tighten the filter an additional 1/2 turn A black coating on the insulator usually means (Figure 22). the air cleaner is dirty. Important: Never clean the spark plugs. 12. Remove the oil fill cap and slowly pour approximately 80% of the specified amount of Always replace the spark plugs when they oil in through the valve cover. -

Page 29: Draining The Fuel Tank

3. Shut off the fuel valve in the hose near the bottom of the fuel tank (Figure 26). When the battery no longer holds a charge, replace Important: Use only a genuine Toro replacement battery. 1. Park the traction unit on a level surface, raise the loader arms, and install the cylinder locks. -

Page 30: Servicing The Battery

3. Remove the wing nut and bolt securing the positive (+) battery post (Figure 27). Slide the battery clamp and strip (under the clamp) and rubber cover over the battery post. remove the clamp and strip (Figure 27). Incorrect battery cable routing could damage the traction unit and cables, causing sparks. - Page 31 Important: Do not overfill the battery because electrolyte (sulfuric acid) can cause severe corrosion and damage to the chassis. 5. Wait five to ten minutes after filling the battery cells. Add distilled water, if necessary, until the electrolyte level is up to the Upper line (Figure 28) on the battery case.

-

Page 32: Drive System Maintenance

disconnect the charger leads from the battery posts (Figure 29). 5. Replace the battery cover. Drive System Maintenance Servicing the Traction Drive Chains Figure 30 Lubricating the Drive Chains 1. Chain guard 3. 1-1/2 to 2-1/2 inches 2. Bottom span of the chain Lubricate the drive chain every 50 operating hours. -

Page 33: Hydraulic System Maintenance

guard and the lower chain span is within 1-1/2 6. Install the replacement hydraulic filter onto the to 2-1/2 inches (3.8 to 6.35 cm) (Figure 30). filter adapter (Figure 32). Tighten it clockwise until the rubber gasket contacts the filter 7. -

Page 34: Checking The Hydraulic Lines

detergent, diesel engine oil (API service CH-4 or higher); refer to Checking Hydraulic Fluid in Operation, page 17. Note: Dispose of used oil at a certified recycling center. 8. Remove and store the cylinder locks and lower the loader arms. Checking the Hydraulic Lines After every 25 operating hours, check the hydraulic... -

Page 35: Storage

Storage B. Run the engine to distribute conditioned fuel through the fuel system (5 minutes). 1. Lower the loader arms, stop the engine, and C. Stop the engine, allow it to cool, and drain remove the key. the fuel tanks; refer to Draining the Fuel Tank. -

Page 36: Troubleshooting

Troubleshooting Problem Possible Cause Corrective Action The starter does not crank 1. The auxiliary hydraulics 1. Move the lever to the lever is not in the neutral neutral position. position. 2. The battery is 2. Charge the battery or discharged. replace it. - Page 37 Problem Possible Cause Corrective Action The engine overheats. 1. The engine load is 1. Reduce ground speed. excessive. 2. The oil level in the 2. Check and add oil to the crankcase is low. crankcase. 3. The cooling ns and 3.

-

Page 38: Schematics

Schematics Electrical Schematic (Rev. A) - Page 39 Hydraulic Schematic (Rev. A)

- Page 43 The use of any add-on or modied parts will be grounds for disallowing a warranty claim made in accordance with this article. The Toro® Company will not be liable under this Article to warrant failures of warranted parts caused by the use of an add-on or modied part.

- Page 44 (Dealer) to obtain guarantee policies for your country, province, or state. If for any reason you are dissatised with your Distributor’s service or have difculty obtaining guarantee information, contact the Toro importer. If all other remedies fail, you may contact us at Toro Warranty Company.