Table of Contents

Advertisement

Quick Links

Download this manual

See also:

Operator's Manual

Form No. 3359-137 Rev A

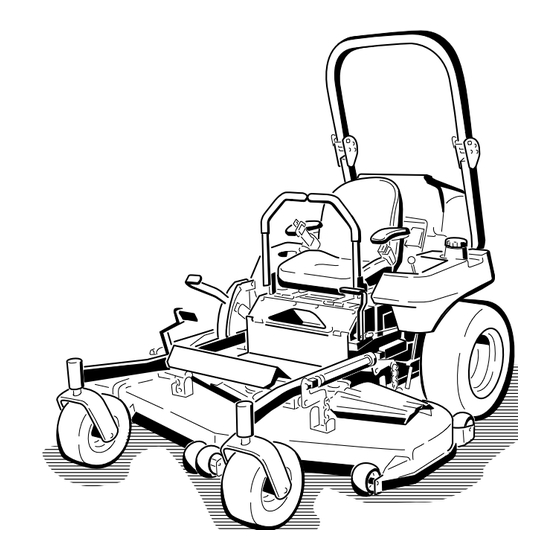

Z590-D Z Master

®

with 60in

or 72in TURBO FORCE

Side

®

Discharge Mower

Model No. 74268—Serial No. 280000001 and Up

Model No. 74268CP—Serial No. 280000001 and Up

Model No. 74269—Serial No. 280000001 and Up

Model No. 74269CP—Serial No. 280000001 and Up

Register at www.Toro.com.

Original Instructions (EN)

Advertisement

Table of Contents

Summary of Contents for Toro 74268CP

- Page 1 72in TURBO FORCE Side ® Discharge Mower Model No. 74268—Serial No. 280000001 and Up Model No. 74268CP—Serial No. 280000001 and Up Model No. 74269—Serial No. 280000001 and Up Model No. 74269CP—Serial No. 280000001 and Up Register at www.Toro.com. Original Instructions (EN)

-

Page 2: Table Of Contents

Whenever you need service, genuine Toro parts, or worthy of special attention. additional information, contact an Authorized Service Dealer or Toro Customer Service and have the model and serial numbers of your product ready. Figure 1 Contents identifies the location of the model and serial numbers on the product. - Page 3 Using the Rollover Protection System Replacing the Drive Belts........44 (ROPS) ............16 Adjusting the Drive Belts ........45 Think Safety First ..........17 Checking and Replacing the Pump Drive Understanding the Audible Alarms ..... 17 Belt ..............46 Operating the Parking Brake ....... 18 Replacing and Tensioning the Alternator Starting and Stopping the Engine ......

-

Page 4: Safety

Safety • Use extra care when handling diesel and other fuels. They are flammable and vapors are explosive. Improper use or maintenance by the operator or owner – Use only an approved container can result in injury. To reduce the potential for injury, –... -

Page 5: Slope Operation

• Be certain that the seat belt can be released quickly decals. in the event of an emergency. • Be aware there is no rollover protection when the • Use only Toro approved attachments. Warranty may roll bar is down. be voided if used with unapproved attachments. -

Page 6: Slope Chart

Slope Chart... -

Page 7: Safety And Instructional Decals

Safety and Instructional Decals Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or lost. 58-6520 1. Grease 1-403005 66-1340 1-523552 65-2690 1-643253 68-8340 98-4387 1. - Page 8 98-5954 105-7798 103-3276 107-1613 103-5881 107-1857 104-2449 104-7759 107-1860 1. Height of cut...

- Page 9 107-1861 107-2102 107-1864 107-2112 107-2114...

- Page 10 Manufacturer’s Mark 1. Indicates the blade is identified as a part from the original machine manufacturer. 107-7673 1. Cutting blade 107-9863 107-7705 107-9864 1. Read the Operator’s Manual. 109-7949 110-2067...

- Page 11 110-2068 1. Read the Operator’s Manual. 115-3562 114-9600 1. Read the Operator’s Manual. 106-7492...

- Page 12 106-9989 107-9309 1. Warning—read the Operator’s Manual for information on charging the battery; contains lead; do not discard. 2. Read the Operator’s Manual. 107-9866 1. Fast 2. Slow 3. Neutral 4. Reverse...

-

Page 13: Product Overview

Hour Meter Product Overview The hour meter records the number of hours the engine has operated. It operates when the engine is running. Use these times for scheduling regular maintenance (Figure 4). Glow Plug Light (Orange Light) The glow plug indicator light turns on when the ignition switch is turned to the on position. -

Page 14: Operation

Operation Note: Determine the left and right sides of the In certain conditions, fuel is extremely machine from the normal operating position. flammable and highly explosive. A fire or explosion from fuel can burn you and others Adding Fuel and can damage property. •... -

Page 15: Checking The Engine Oil Level

Filling the Fuel Tank 1. Shut the engine off and set the parking brake. In certain conditions during fueling, static 2. Clean around each fuel tank cap and remove the electricity can be released causing a spark cap. Add fuel to both fuel tanks, until the level is which can ignite the fuel vapors. -

Page 16: Using The Rollover Protection System (Rops)

Using the Rollover Protection System (ROPS) To avoid injury or death from rollover: keep the roll bar in the raised locked position and use the seat belt. Ensure that the rear part of the seat is secured with the seat latch. Figure 6 1. -

Page 17: Think Safety First

Think Safety First Please read all safety instructions and symbols in the safety section. Knowing this information could help you or bystanders avoid injury. Operating on wet grass or steep slopes can cause sliding and loss of control. Wheels dropping over edges can cause rollovers, which may result in serious injury, death or drowning. -

Page 18: Operating The Parking Brake

brake is disengaged and the lever will rest against the brake stop. Figure 10 Figure 11 Continuous Audible Alarm 1. Parking brake-ON 3. Brake Stop 2. Parking brake-OFF The continuous audible alarm alerts the user that the engine is over heating. Refer to Servicing the Cooling System. -

Page 19: Starting The Engine In Cold Weather

Figure 12 1. Ignition switch 5. Hour meter 2. Throttle control 6. Fuel cap Figure 14 3. Glow plug light 7. Volt meter 1. Throttle—fast 2. Throttle—slow 4. Power take off (PTO) 8. Engine Temperature Switch gauge Starting the Engine in Cold Weather Important: Use starting cycles of no more than (Below 14°F or -10°C) 30 seconds per minute to avoid overheating the... -

Page 20: Operating The Power Take Off (Pto)

Disengaging the PTO Important: Make sure that the fuel selector valve is closed before transporting or storing To disengage, push the PTO switch to the off position the machine, as fuel leakage may occur. Set the (Figure 15). parking brake before transporting. Important: Make sure to remove the key as The Safety Interlock System the fuel pump may run and cause the battery... -

Page 21: Driving Forward Or Backward

control levers to neutral lock position. Now start To stop, pull the motion control levers to the neutral the engine. While the engine is running, release position. the parking brake, engage the PTO and rise slightly from the seat; the engine should stop. 4. -

Page 22: Adjusting The Control Lever Resistance

Children or bystanders may be injured if they move or attempt to operate the tractor while it is unattended. Always remove the ignition key and set the parking brake when leaving the machine unattended, even if just for a few minutes. Adjusting the Control Lever Resistance Figure 18... -

Page 23: Adjusting The Flow Baffle

Note: The two middle rollers will not have a spacer (Figure 21). 4. Select a hole so the anti-scalp roller is positioned to the nearest corresponding height-of-cut desired. 5. Install the flange nut bushing, spacer, and bolt. Torque to 40-45 ft-lb (54-61 N-m) (Figure 20 , Figure 21 and Figure 22 ). -

Page 24: Positioning The Flow Baffle

Position A • Allows increased ground speed in heavy conditions. This is the full rear position. The suggested use for this • This position is similar to the benefits of the Toro position is a follows. SFS mower. • Use for short, light grass mowing conditions. -

Page 25: Unlatching The Seat

1. To adjust, move the lever sideways to unlock seat (Figure 27). Figure 28 1. Back rest knob 2. Right-side arm rest Figure 27 1. Seat suspension knob 2. Seat position adjustment lever Unlatching the Seat 2. Slide the seat to the desired position and release Push the seat latch rearward to unlatch the seat. -

Page 26: Pushing The Machine By Hand

Pushing the Machine by Hand Important: Always push the machine by hand. Without the grass deflector, discharge cover, Never tow the machine because hydraulic damage or complete grass catcher assembly mounted may occur. in place, you and others are exposed to blade contact and thrown debris. -

Page 27: Loading Machines

Loading Machines Use extreme caution when loading units on trailers or trucks. One full width ramp that is wide enough to extend beyond the rear tires is recommended instead of individual ramps for each side of the unit (Figure 31). The lower rear section of the tractor frame extends back between the rear wheels and serves as a stop for tipping backward. -

Page 28: Operating Tips

Driving off the Z Stand 1. Remove the chocks or blocks. 2. Raise the latch to the unlocked position (Figure 34). Figure 32 1. Z Stand 4. Bracket Pin 2. Latch 5. Bottom of slot 3. Bracket 3. Raise the latch. Swing the stand foot out front and Figure 34 slide stand toward machine, into the bottom of slot 3. -

Page 29: Cutting Speed

If a blade is damaged or worn, replace it immediately with Mow at Correct Intervals a genuine TORO replacement blade. Normally, mow every four days. But remember, grass grows at different rates at different times. So to maintain the same cutting height, which is a good practice, mow more often in early spring. -

Page 30: Maintenance

Maintenance Recommended Maintenance Schedule(s) Maintenance Service Maintenance Procedure Interval • Check cooling system level. After the first 8 hours • Check the hydraulic fluid. • Change the hydraulic filter. After the first 25 hours • Change the engine oil. After the first 50 hours •... -

Page 31: Lubrication

If you leave the key in the ignition switch, someone could accidently start the engine and seriously injure you or other bystanders. Remove the key from the ignition and disconnect the wire from the spark plug(s) before you do any maintenance. -

Page 32: Where To Add Light Oil Or Spray Lubrication

Grease the Idler Arms Important: Make sure cutting unit spindles are full of grease weekly. 1. Grease the cooling fan belt idler arm (Figure 37). 1. Disengage the PTO, move the motion control levers 2. Grease the drive belt idler arms (Figure 37). to the neutral locked position and set the parking brake. -

Page 33: Engine Maintenance

Engine Maintenance Servicing the Air Cleaner Note: Service the air cleaner more frequently if operating conditions are extremely dusty or sandy. Removing the Filters 1. Disengage the PTO, move the motion control levers to the neutral locked position and set the parking brake. -

Page 34: Servicing The Engine Oil

Important: Do not press on the soft inside area of the filter. 4. Install the air cleaner cover with the side indicated as UP facing up and secure the latches (Figure 40). 5. Install the front engine panel. Servicing the Engine Oil Oil Type: High-quality detergent oil classified “API Service CF or CF-4"... -

Page 35: Changing The Engine Oil Filter

Adding Engine Oil 1. Tilt the seat forward and remove the front engine panel (Figure 43). Figure 45 1. Note the clearance left in the filler opening. 5. Replace the dipstick and install the front engine panel. Figure 43 6. Start the engine and run it at idle for 5 minutes. 1. -

Page 36: Fuel System Maintenance

Fuel System Maintenance Servicing the Fuel Filter Draining the Water Separator Figure 46 Service Interval: Every 40 hours 1. Drain plug 3. Dip stick 1. Position the machine on a level surface. 2. Oil filter 2. Disengage the PTO, move the motion control levers to the neutral locked position and set the parking brake. -

Page 37: Servicing The Fuel Tank

Changing the Fuel Filter Electrical System Service Interval: Every 400 hours/Yearly (whichever Maintenance comes first) (more often in dirty or dusty conditions). Servicing the Battery Never install a dirty fuel filter if it is removed from the fuel line. Warning 1. -

Page 38: Charging The Battery

2. First, install the positive (red) battery cable to positive (+) battery terminal. Incorrect battery cable routing could damage 3. Then install the negative battery cable and ground the machine and cables causing sparks. Sparks wire to the negative (-) battery terminal. can cause the battery gasses to explode, 4. -

Page 39: Servicing The Fuses

Drive System Maintenance Adjusting the Tracking The machine has a knob for adjusting the tracking located under the seat. Important: Adjust the handle neutral and hydraulic pump neutral before adjusting the tracking. Refer to Adjusting the Handle Neutral in Controls System Maintenance , page 47 and Adjusting the Hydraulic Figure 51 Pump Neutral in Hydraulic System Maintenance ,... -

Page 40: Checking The Tire Pressure

Checking the Tire Pressure 8. Tighten the nut until the next set of slots line up with the hole in the shaft (Figure 55). Service Interval: Every 50 hours or monthly, whichever 9. Replace the cotter pin. occurs first. Check the pressure at the valve stem (Figure 54). Maintain the air pressure in the rear tires at 13 psi (90 kPa). -

Page 41: Cooling System Maintenance

Cooling System Maintenance Servicing the Cooling System Discharge of hot pressurized coolant or touching hot radiator and surrounding parts can cause severe burns. • Do not remove the radiator cap when the engine is hot. Always allow the engine to cool at least 15 minutes or until the radiator cap is cool enough to touch without burning Figure 56... -

Page 42: Cleaning The Cooling System

Cooling System Capacity: 128 ounces (3.8 l) 4. Remove debris from the screen on the engine cover. Note: Do not open the radiator cap. Doing this may 5. Tilt the engine cover forward. induce air into the cooling system. 6. Remove debris from the radiator core and engine. 1. -

Page 43: Brake Maintenance

Brake Maintenance Adjusting the Parking Brake Service Interval: Every 25 hours Every 200 hours 1. Disengage the brake lever (lever down). 2. Measure the length of the spring. The measurement should be 2-3/4 inch (70 mm) between the washers (Figure 58). 3. -

Page 44: Belt Maintenance

Belt Maintenance Inspecting the Belts Service Interval: Every 100 hours Check the belts for squealing when the belt is rotating, blades slipping when cutting grass, frayed belt edges, burn marks and cracks are signs of a worn mower belt. Replace the mower belt if any of these conditions are evident. -

Page 45: Adjusting The Drive Belts

Adjusting the Drive Belts 1. Disengage the PTO, move the motion control levers to the neutral locked position and set the parking brake. 2. Stop the engine, remove the key, and wait for all moving parts to stop before leaving the operating position. -

Page 46: Checking And Replacing The Pump Drive Belt

Replacing and Tensioning the Alternator Belt Replacing the Alternator Belt Service Interval: Every 50 hours—Check the alternator belt. 1. Disengage the PTO, move the motion control levers to the neutral locked position and set the parking brake. 2. Stop the engine, remove the key, and wait for all moving parts to stop before leaving the operating Figure 64 position. -

Page 47: Controls System Maintenance

Controls System 5. If the deflection is correct, torque the upper bolt to 170 in-lb (19 N-m) and the bottom bolt to 45 ft-lb Maintenance (61 N-m) (Figure 67). 6. Install the pump drive belt; refer to Replacing the Pump Drive Belt. Adjusting the Control Handle 7. -

Page 48: Hydraulic System Maintenance

Hydraulic System 9. Apply slight rearward pressure on the motion control lever, turn the head of the adjustment bolt Maintenance in the appropriate direction until the control lever is centered in the neutral lock position (Figure 69). Note: Keeping rearward pressure on the lever will Servicing the Hydraulic keep the pin at the end of the slot and allow the System... - Page 49 2. Stop the engine, remove the key, and wait for all moving parts to stop before leaving the operating position. Important: Do not substitute automotive oil filter or severe hydraulic system damage may result. 3. Place drain pan under filter, remove the old filter and wipe the filter adapter gasket surface clean (Figure 71).

-

Page 50: Bleeding The Hydraulic System

Bleeding the Hydraulic System The traction system is self bleeding, however, it may be necessary to bleed the system if fluid is changed or after work is performed on the system. 1. Raise rear of the machine so wheels are off the ground and support with jack stands. -

Page 51: Setting The Hydraulic Pump Neutral Position

Setting the Hydraulic Pump Neutral Position Note: Adjust the handle neutral first. That needs to be correct before the following adjustment can be made. This adjustment must be made with drive wheels turning. Mechanical or hydraulic jacks may fail to support machine and cause a serious injury. -

Page 52: Mower Deck Maintenance

Mower Deck Maintenance Leveling the Mower at Three Positions Important: There are only three measuring positions needed to level the mower. Setting Up the Machine 1. Position the mower on a flat surface. 2. Disengage the PTO, move the motion control levers to the neutral locked position and set the parking brake. - Page 53 2. Measure the right blade at the B location, from a level surface to the cutting edge of the blade tip (Figure 76). 3. Record this measurement. This measurement needs to be 3-1/8 to 3-1/4 inches. 4. Position the left blade side-to-side (Figure 76). 5.

-

Page 54: Servicing The Cutting Blades

If a blade is damaged or worn, 2. Stop the engine, remove the key, and wait for all replace it immediately with a genuine Toro replacement moving parts to stop before leaving the operating blade. For convenient sharpening and replacement, you position. -

Page 55: Removing The Blades

To ensure optimum procedure until the blade is balanced. performance and continued safety conformance of the machine, use genuine TORO replacement blades. Replacement blades made by other manufacturers may result in non-conformance with safety standards. -

Page 56: Replacing The Grass Deflector

Installing the Blades Important: The grass deflector must be able to lower down into position. Lift the deflector up 1. Install the blade onto the spindle shaft (Figure 84). to test that it lowers into the full down position. Important: The curved part of the blade must be pointing upward toward the inside of the mower to ensure proper cutting. -

Page 57: Cleaning

Cleaning Storage Cleaning and Storage Cleaning Under the Mower 1. Disengage the power take off (PTO), set the parking Service Interval: Before each use or daily brake, and turn the ignition key to Off. Remove the key. Remove the grass buildup under the mower daily. 2. - Page 58 Note: A fuel stabilizer/conditioner is most effective when mixed with fresh fuel and used at all times. B. Run the engine to distribute conditioned fuel through the fuel system (5 minutes). C. Stop the engine, allow it to cool, and drain the fuel tank;...

-

Page 59: Troubleshooting

Troubleshooting Problem Possible Cause Corrective Action Starter does not crank 1. Blade control (PTO) is engaged. 1. Move the blade contro (PTO) to disengaged. 2. Parking brake is not on. 2. Set the parking brake. 3. Operator is not seated. 3. - Page 60 Problem Possible Cause Corrective Action Uneven cutting height. 1. Blade(s) not sharp. 1. Sharpen the blade(s). 2. Cutting blade(s) is/are bent. 2. Install new cutting blade(s). 3. Mower is not level. 3. Level the mower from side-to-side and front-to-rear. 4. Underside of mower is dirty. 4.

-

Page 61: Schematics

Schematics Wire Diagram (Rev. -) - Page 62 Notes:...

- Page 63 Notes:...

- Page 64 Countries Other than the United States or Canada Customers who have purchased Toro products exported from the United States or Canada should contact their Toro Distributor (Dealer) to obtain guarantee policies for your country, province, or state. If for any reason you are dissatised with your Distributor’s service or have difculty obtaining guarantee information, contact the Toro importer.